Research gathered by the Bureau of Labor Statistics shows that falls were the second most common cause of fatal occupational injuries in 2023. Many of those falls were caused by improper use of ladders. Ladders are a versatile tool that come with plenty of limitations and inherent dangers. Extension ladders, also known as non-self-supporting ladders, are probably one of the most used and misused pieces of access equipment. Choosing the right ladder and knowing how to properly, and safely use it is important.

Purchasing the right types of ladders and maintaining them so that they comply with applicable standards is the responsibility of the employer. Employers are required by the Occupational Safety and Health Administration (OSHA) to provide training on the safe use of ladders per OSHA 29 CFR§ 1926.1060. Safety inspections for ladders should be done on a regular basis to prevent injury. If a ladder is found to be damaged, it should be marked with a tag stating “Do Not Use,” and removed from service.

Choosing the Right Ladder

Extension ladders are made from wood, aluminum, and fiberglass and come in various lengths. Choosing the right ladder for the job is very important. Because wood and metal are great conductors of electricity, it is best to use a fiberglass ladder if you are doing electrical work.

Height Restrictions

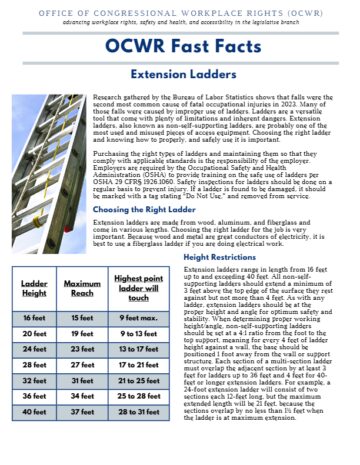

Extension ladders range in length from 16 feet up to and exceeding 40 feet. All non-self-supporting ladders should extend a minimum of 3 feet above the top edge of the surface they rest against but not more than 4 feet. As with any ladder, extension ladders should be at the proper height and angle for optimum safety and stability. When determining proper working height/angle, non-self-supporting ladders should be set at a 4:1 ratio from the foot to the top support, meaning for every 4 feet of ladder height against a wall, the base should be positioned 1 foot away from the wall or support structure. Each section of a multi-section ladder must overlap the adjacent section by at least 3 feet for ladders up to 36 feet and 4 feet for 40-feet or longer extension ladders. For example, a 24-foot extension ladder will consist of two sections each 12-feet long, but the maximum extended length will be 21 feet, because the sections overlap by no less than 1½ feet when the ladder is at maximum extension.

| Ladder Height | Maximum Reach | Highest point ladder will touch |

|---|---|---|

| 16 feet | 15 feet | 9 feet max. |

| 20 feet | 19 feet | 9 to 13 feet |

| 24 feet | 23 feet | 13 to 17 feet |

| 28 feet | 27 feet | 17 to 21 feet |

| 32 feet | 31 feet | 21 to 25 feet |

| 36 feet | 34 feet | 25 to 28 feet |

| 40 feet | 37 feet | 28 to 31 feet |

Load Limits

Even though they may all look the same, each ladder has a different load limit, as shown in the ladder load limit table below. Your weight and the weight of the tools or equipment being carried are factored into the load limit of the ladder. You want to make sure that the ladder you are using can handle the combined weight of the person and the tools or equipment being carried up and down the ladder, otherwise the ladder may become unstable and cause injury.

| Ladder Type | Load Limit | Description |

|---|---|---|

| Type 1-AA | 375 lbs. | Special Duty |

| Type 1-A | 300 lbs. | Heavy Duty Industrial |

| Type I | 250 lbs. | Heavy Duty |

| Type II | 225 lbs. | Medium Duty |

| Type III | 200 lbs. | Light Duty |

Safety Inspection

Employees are required by OSHA to conduct safety inspections before each use to assist in preventing injury, detecting corrosion, and identifying normal wear and tear according to 1910.23(b)(9). Inspect all extension ladders for loose rungs. Rungs should be sturdy, clean, and not slippery from dirt or oil. Inspect the rung locks for any cracks or bends that could prevent them from working properly. The side rails should be strong and visibly free of cracks, breaks, splits, and bent edges. Nails, bolts, screws, and other fasteners should be tight. Any rope and pulley system should be inspected for fraying and rotting, and checked for loose pulleys and metal spurs that could cause rope damage. Last but not least, examine the feet and make sure the nonslip pads are in good shape.

Remember: Turn broken ladders in for repair or take them completely out of service marking

them “Do Not Use,” to protect coworkers and others from needless injury.

Training Requirements

OSHA requires employers to provide training that enables employees to recognize hazards related to ladders and how to minimize them. A competent person should be designated to train employees on the following:

- the nature of fall hazards in the work area,

- correct procedures for placement and care in handling ladders,

- maximum intended load-carrying capacities of ladders used, and

- ladder inspection points.

Retraining should be provided for each employee as necessary to maintain understanding and knowledge.

Extension Ladder Dos

- Select the appropriate ladder for the job.

- Inspect before use.

- Make sure the ladder rises at least three feet above the upper landing surface.

- Secure the ladder near the top to prevent swaying or walking.

- Secure the base by either staking or burying to prevent slipping.

- Make sure that the ladder is on a secure firm base and that you have utilized the 4:1 ratio.

- When climbing up or down the ladder, always face the ladder.

- Maintain 3-point contact with 2 hands and a foot or both feet and a hand.

- Be sure that all locks on an extension ladder are properly engaged.

- Use a tool belt to keep your hands free or pull materials up with a line.

- Use an extension ladder for access, not as a work platform. It is safer to work from scaffolding, scissor lifts, or boom lifts.

- Only allow one person on the ladder at a time.

- Read and follow all labels/markings on the ladder.

Extension Ladder Don’ts

- Do not move or shift a ladder while a person or equipment is on the ladder.

- Do not stand on the three top rungs of a straight, single, or extension ladder.

- Do not use ladders near energized electrical wires; maintain 10-feet minimum clearance of all electrical or power lines.

- Never balance the ladder on other objects to reach higher jobs.

- Never over reach to do your work.

- If you are leaning to the right, left, or backwards, move the ladder into a better position.

- Do not exceed the overlap required for safety. At a minimum, there should be a 3-foot overlap to safely maintain the load limit requirements.

- Do not exceed the maximum load rating of a ladder.

- Do not place ladder feet or base on moveable objects or unsecured surfaces.

Remember: Always keep the ladder on a secure footing. Even if you are just a few feet off the ground, an awkward fall can kill you or cause serious injury.